How is Digital Inventory Management Used in Additive Manufacturing?

Würth Additive Group’s 3D printing services offer a streamlined and efficient method to simplify your supply chain, reduce development times, and increase the ability to adapt to customers’ needs.

Würth’s 3D Printing Delivers:

- Decades of experience in C-Parts and supply chain management

- Lower purchasing costs and significant cost savings so you can concentrate on your core business

- Engineering expertise during the design phase, saving you time and money with more efficient fastening solutions. Reducing component count and increasing installation efficiency adds to your bottom line.

- A qualified sourcing team to verify dimensions and provide your printed part to our suppliers. A model in hand, with exact dimensions, means efficiency is increased and down-time risk is lessened.

- An on-demand, knowledgeable sales team ready to discuss the different materials and printing capabilities available.

- Printing resources from value-oriented to the highest specification available

We offer a digital industrial solution for:

Engineers:

- “Metal on-demand” capabilities expand the scope of problem-solving on your production floor

- Wide range of metal and polymer materials allow you to design for strength, stress, and impact

- Quickly prototype new ideas at a low cost to provide the best solution

- Software that allows an engineering team to have the same standardized parts library nationwide or around the globe

Line Supervisors:

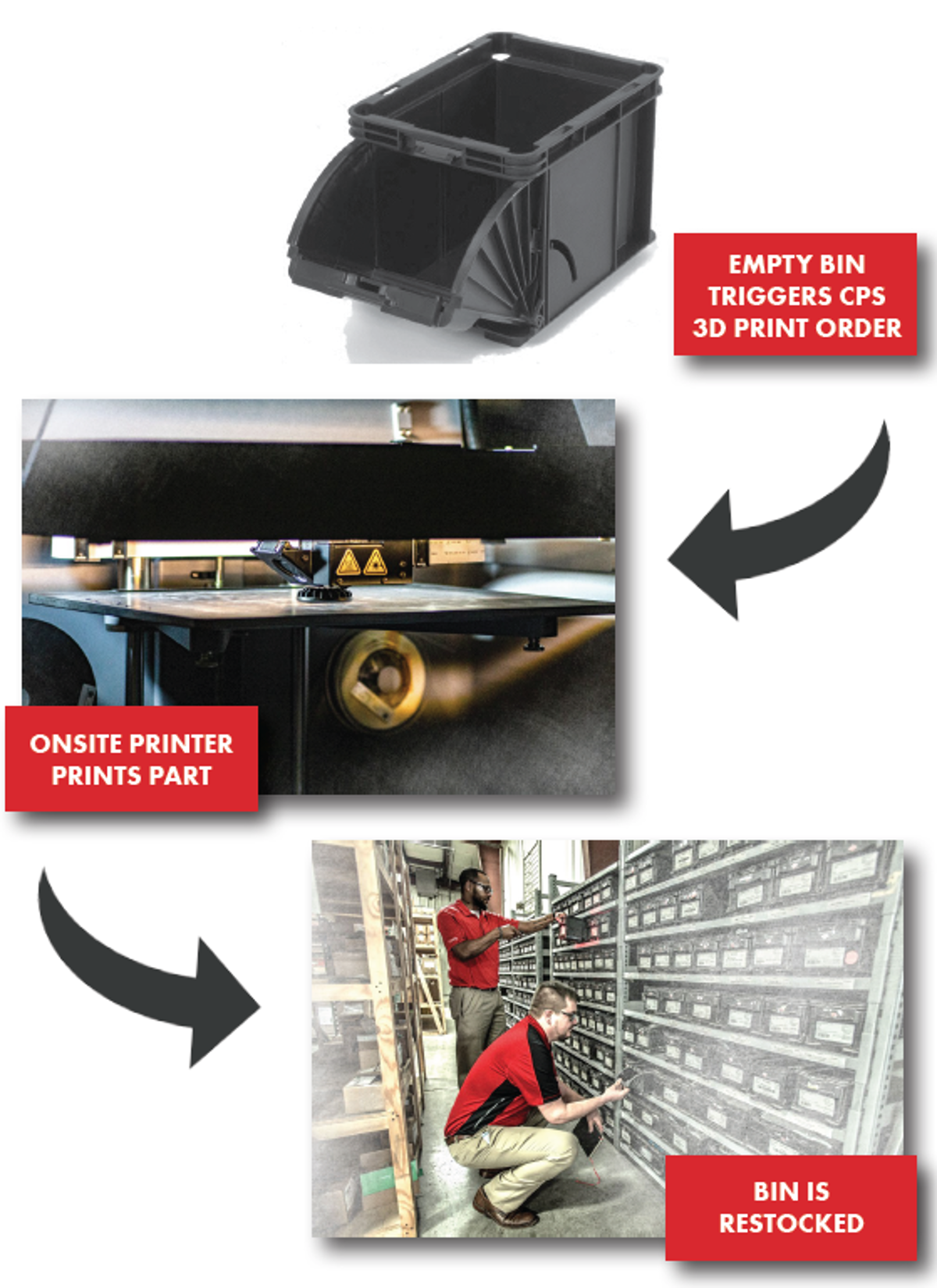

- Digital Kanban of replacement parts/tools/fixtures keep the line running with minimal downtime or cost

- Increase speed, efficiency, or ergonomics in assembly with custom tools

- Cut down on standing inventory space by keeping a digital library of slow running components

Purchasers:

- We provide 3D drawings, prototypes, and recommendations on potential cost-saving

- opportunities

- As you gather forecast information we can give prospective pricing to help you project costs

- Take ideas from prototype, to pilot build, to full production - faster than the competition

- Accelerate and supports a SKU’s lifecycle

Company Management:

- Connect any number of facilities with a standardized process

- We curate your digital parts library, instantly standardizing your parts catalog across sites

- New tools or components can easily launch at all facilities, streamlining logistics and ensuring the right parts are at all locations

- The Würth CPS and 3D programs give a worldwide platform to cut waste in your supply chain

Learn more about Würth Additive Group and shop industrial 3D printers, training sessions, consumables, and more here.